[ad_1]

Scientists from the University of the West of England and the National University of Singapore have published a new paper in the journal Advanced Science reviewing recent advances in wearable electronic textiles.

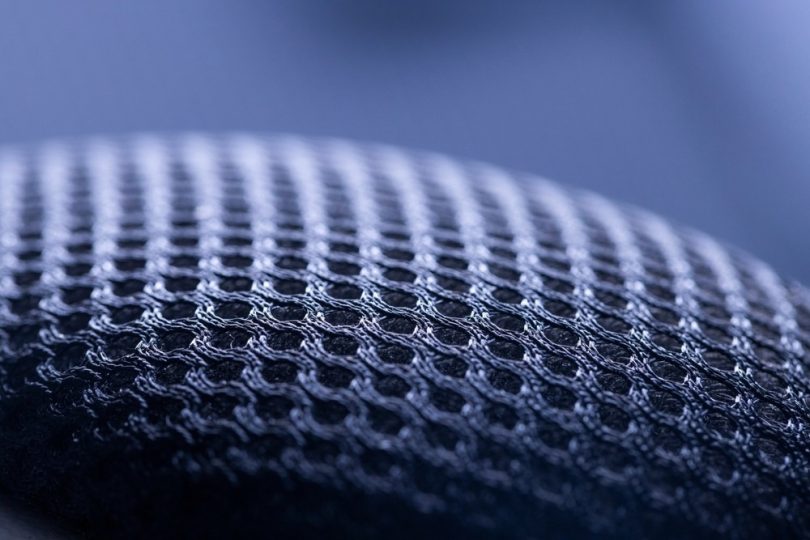

Study: Smart Electronic Textile-Based Wearable Supercapacitors. Image Credit: b.asia/Shutterstock.com

In the paper, several key research areas and perspectives have been comprehensively explored. Thus, the research makes an important contribution to this emerging field of smart textiles and materials science research.

Wearable Electronic Textiles: An Overview

Recent advances in materials science, miniaturization, nanotechnology, and wireless capabilities have accelerated the evolution of wearable electronic textiles. This class of advanced, functional materials has found application in areas such as healthcare, environmental monitoring, the military, sportswear, and safety instrumentation. Devices are classified as 1D fiber/yarn devices and 2D fabric shaped devices. Limited numbers of 3D-shaped devices have been reported

The field concentrates on the development of integrated, intelligent systems which are in contact with human skin, and could potentially be further integrated with biological elements such as muscles, nerves, and ligaments. However, there are some key challenges that hinder the full commercialization of wearable electronic textiles which must be overcome by researchers.

Electrochemical Energy Storage Systems

Wearable electronic textiles require reliable and efficient power sources, much like any other electronic device. However, flexible devices have special requirements that traditional bulky and inflexible electrochemical energy storage systems such as batteries cannot satisfy. Therefore, this facilitates the development of novel flexible and comfortable energy storage systems which retain their efficiency and stability.

Ideal energy storage devices should possess both high energy and power density. For wearable applications, these components should also possess ultra-flexibility, and be lightweight, durable, comfortable, and safe to use.

Types of electrochemical energy storage systems include batteries, supercapacitors, and fuel cells. Pseudo capacitors, electrical double-layer capacitors, hybrid capacitors, and Li-ion batteries have been researched in recent years for wearable applications. Various techniques are employed to evaluate the electrochemical performance of components, such as cyclic voltammetry and electrochemical impedance spectroscopy.

Materials

Several suitable materials for wearable electronic textiles have been highlighted in the paper. Textiles are used as the substrate for components such as supercapacitors, and several natural fibers have been explored in research such as cotton, wool, and silk. Polymeric substrates have also been evaluated, such as polyamides, polyesters, nylon, and thermoplastic polyurethane.

Textile choices for end products depend on their physical, tensile, chemical, and thermal properties. Low-cost, non-toxic, and sustainable textiles have already been integrated into prototype wearable electronics systems.

Electroactive materials have been investigated for use in components such as electrodes, including carbonaceous materials such as carbon nanotubes, carbon black, activated carbon, graphene, and graphene oxide. Conductive polymers have also been researched, as well as metal oxides and 2D materials such as transition metal chalcogenides and MXenes.

Electrolytes are also a key component of energy harvesting and storage systems such as supercapacitors. Aqueous electrolytes, organic electrolytes, ionic liquids, polymer electrolytes, gel polymer electrolytes, polymer-salt complex electrolytes, and composite electrolytes have emerged as potential candidates in wearable electronic textile and device research.

Fabrication of Wearable Electronic Textiles

Wearable electronic textiles and components such as electrodes can be fabricated using various methods. Active materials can be directly coated on textile substrates to improve their electrical conductivity. Coating techniques explored in research include dip coating, chemical vapor deposition, tape casting, physical vapor deposition, and wrapping.

Conductive materials can be integrated with fabrics using methods such as braiding, embroidery, knitting, and weaving. Active materials can also be printed directly onto textile substrates using additive manufacturing methods such as inkjet printing and screen printing. Melt spinning, wet spinning, and electrospinning have also emerged as attractive fabrication methods.

Key Properties of Wearable Supercapacitors

The paper has explored key properties required for efficient, durable, flexible, and wearable supercapacitors. Two main properties these important energy storage components need are flexibility and resistance to mechanical deformation. Several techniques are employed in research to test these properties, such as bending, twisting, winding, and other deformation tests over hundreds of cycles.

Components must be able to retain critical electrical properties over multiple cycles, such as capacitance retention. Additionally, they must be safe to use even under extreme mechanical stress. Several studies have investigated the design of supercapacitors which meet all these property requirements, with varying degrees of success.

Challenges, Future Directions, and Outlook

A number of challenges that hinder the full commercialization of wearable electronic textiles have been highlighted in the paper. Performance retention after multiple washing cycles, safety issues such as toxicity for both users and the environment, and technical challenges with materials and flexible device components are the focus of research currently.

Improving cost performance, sustainable manufacturing, multifunctionality, and industrial scalability are key issues that must be addressed by scientists working in the field of wearable electronics.

Whilst these challenges are highly complex, wearable electronic textile-based devices have a good outlook. There is an increasing demand for these innovative devices in numerous industries, which facilitates intensive research. The electronic textile and smart clothing market is predicted to surpass $15,018.9 million by 2028.

Significant progress is being made in research, and the new review paper in the journal Advanced Science provides a noteworthy contribution to the field of smart, wearable electronic textile-based devices.

More from AZoM: Strong and Heat-Resistant Synthetic Fiber Kevlar and its Composites

Further Reading

Islam, M.R et al. (2022) Smart Electronic Textile-Based Wearable Supercapacitors Advanced Science [online] onlinelibrary.wiley.com. Available at:

https://onlinelibrary.wiley.com/doi/10.1002/advs.202203856

[ad_2]

Source link